What are the Properties of Offset Sheet-fed Cold Foil?

Offset sheet-fed cold foil is a cutting-edge decorative printing solution widely embraced in industries where packaging and visual impact are key. Known for its high metallic gloss, outstanding transfer quality, and versatile compatibility, this cold foil technology is changing packaging design and premium print production.

In this article, we will dive deep into the specific properties that make offset sheet-fed cold foil an ideal choice for various applications, examine the substrates it supports, and look at why top cold foil manufacturers like Dragon Foils are leading the charge with advanced materials tailored for modern needs.

Offset Sheet-fed Cold Foil

Offset sheet-fed cold foil, also known as cold transfer foil or cold stamping foil, is a decorative metallization process where metallic foil is transferred to a substrate using a standard offset printing press. Unlike traditional hot foil stamping, this method does not require heat or custom stamping dies, making it faster, more cost-effective, and compatible with inline printing processes.

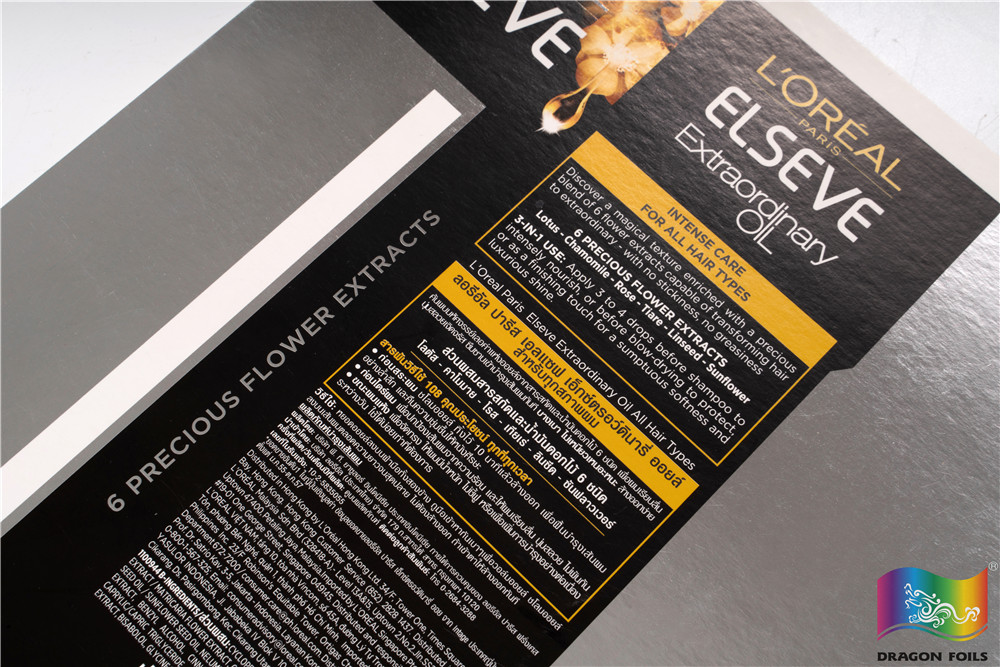

This foil transfer method is especially valuable in industries like luxury packaging, tobacco packaging, greeting cards, book covers, and cosmetic cartons, where visual appeal and detailed design play a critical role in consumer attraction and brand identity.

OSC Series Offset Sheet-fed Cold Foil

Key Properties of Offset Sheet-fed Cold Foil

Let's break down the core features that define a high-performance cold foil:

Specially Designed for Both Conventional and UV Applications

Modern offset sheet-fed cold foils are engineered for dual compatibility, meaning they perform efficiently in both conventional offset printing and UV-curing systems. This makes them suitable for printers working with either technology or hybrid systems. The flexibility enables broader adoption across various press configurations and production environments.

High Metallic Gloss for Maximum Visual Impact

One of the standout features of cold foil is its brilliant metallic finish, which can mimic the appearance of silver, gold, holographic patterns, and more. The high gloss level enhances contrast, depth, and sheen, allowing designers to create attention-grabbing packaging with sophisticated elegance.

This feature is essential in competitive industries like cosmetics and luxury goods, where the metallic effect significantly boosts perceived value.

Smooth Release and Optimal Performance for High-Speed Printing

A quality cold foil must release cleanly from its carrier film during the transfer process. Offset sheet-fed cold foils feature a smooth and controlled release layer, ensuring high-speed application without misregistration or tearing. This is particularly advantageous for long-run commercial print jobs, helping maintain print consistency and reduce downtime.

Excellent Transfer Quality: Fine Details, Halftones, and Large Areas

Cold foils today are optimized for intricate design work. They offer excellent transfer quality, which means the foil adheres accurately even on:

● Fine line elements

● Thin typography

● Halftone gradients

● Broad coverage areas

This eliminates common issues like missing foil in fine details, cracking in solid areas, and pinholes in the transferred image. Such quality is vital for industries with stringent aesthetic standards, such as high-end spirits packaging or premium retail boxes.

Broad Adhesion to Varied Substrates

Offset cold foils are designed to adhere well to a wide array of substrates, including:

● Coated paper

● Folding carton board

● Printed or unprinted surfaces

● Non-absorbent films like PE, PP, and PET

This makes cold foil an adaptable choice for plastic packaging, laminated cartons, and synthetic label stock.

Outstanding Overprintability

Offset sheet-fed cold foils support strong ink adhesion, making them ideal for full-color illustrations, logos, or text elements layered over metallic foil. This property unlocks creative freedom for designers, brand managers, and print specialists seeking to produce richly layered visual effects.

Compliant with Safety and Environmental Standards

Environmental safety is becoming more important in material selection. Offset cold foils from reputable manufacturers meet essential international standards, including:

● ROHS (Restriction of Hazardous Substances)

● REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

● Low VOC (Volatile Organic Compounds) emission compliance

These certifications ensure the foil is safe for packaging food, cosmetics, and tobacco products, while also reducing the environmental footprint of the production process.

Typical Applications of Offset Sheet-fed Cold Foil

Offset sheet-fed cold foils are used in a wide variety of applications, especially where premium packaging and visual appeal are priorities:

● Tobacco packaging – Foils help convey prestige and exclusivity.

● Greeting cards – Add shimmer and luxury without expensive stamping tools.

● Book covers – Make titles and design elements pop on retail shelves.

● Cosmetics and skincare boxes – Enhance perceived value and shelf presence.

● Wine and spirits labels – Combine foil and print to achieve elegant branding.

● Consumer electronics packaging – Reinforce sleek, high-tech aesthetics.

Compatible Substrates

Offset cold foil is formulated to perform well on a variety of surfaces. These include:

● Gloss-coated papers and varnished boards

● Folding cartons with inline coatings

● Plastic films such as PE (Polyethylene), PP (Polypropylene), and PET (Polyester)

● Laminated paperboard and synthetic sheets

● Printed and non-absorbent media

The wide compatibility makes cold foil an excellent solution for multi-substrate print environments, particularly when working with both paper and film-based packaging materials.

Why Choose Dragon Foils for Cold Foil Applications?

If you're looking for a reliable and performance-driven solution for offset sheet-fed cold foil, Dragon Foils is a trusted name in the industry. Known for their innovative cold transfer foil products, Dragon Foils offers materials that meet the highest expectations in terms of:

● Gloss and metallic brilliance

● Compatibility with both UV and conventional offset

● High-speed transfer performance

● Eco-certifications for sustainable printing

● Strong adhesion and flawless release

Dragon Foils continuously invests in R&D to meet the evolving demands of modern packaging design, helping printers and brand owners achieve next-level results without compromising on efficiency or quality.

Conclusion

Offset sheet-fed cold foil stands out as a powerful tool in the arsenal of modern printers and packaging designers. Its unique properties—including high gloss, precise transfer, wide substrate compatibility, and overprintability—make it suitable for diverse industries and high-value products.

When choosing a cold foil for your next project, look for proven suppliers like Dragon Foils, whose advanced formulations guarantee reliable results and exceptional visual appeal. With the right foil in hand, you can elevate their packaging to new heights while ensuring efficient, eco-friendly production.