How to Choose the Best Foil Based on Substrate Material?

Whether you are designing packaging for cosmetics, high-end beverages, or specialty stationery, the choice of foil can make or break the visual impact. However, one of the most overlooked aspects of foil application is the substrate material itself. Choosing the right foil isn't just about color or finish; it's about ensuring compatibility with the surface, durability, and the final aesthetic.

In this article, we'll break down how to select the right foil based on different substrate materials, helping you make informed decisions that elevate your projects.

Understanding Substrate Materials

In printing and finishing, a substrate is the material onto which the foil is applied. Common substrates include paper, cardboard, plastic, synthetic materials, and specialty surfaces like textiles or laminates. Each substrate has unique properties such as texture, porosity, heat tolerance, and flexibility, which directly affect foil adhesion and overall performance.

For example, smooth coated papers are ideal for high-shine metallic foils because they allow even transfer and crisp edges. On the other hand, rough or uncoated surfaces may require specialized foils or adhesives to achieve the same visual quality. Understanding these nuances is key to selecting foils that stick well and look flawless.

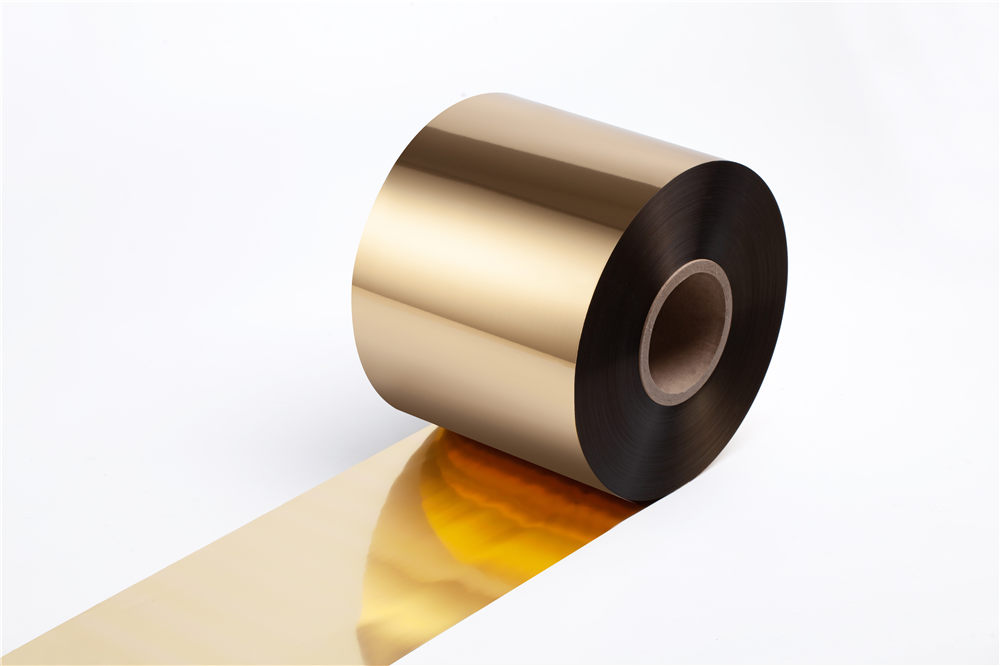

Hot Stamping Foils and Their Substrate Compatibility

Hot stamping is the traditional foil application method, using heat and pressure to transfer metallic or pigmented foils onto a substrate. The process relies on the substrate's ability to withstand heat without warping or discoloring.

Best Substrates for Hot Stamping:

● Coated Papers and Cardstocks: Smooth coated papers offer excellent adhesion and a polished finish. Ideal for luxury packaging, wedding invitations, or greeting cards.

● Synthetic Papers: Materials like Tyvek or PVC-based sheets can take hot stamping foils well, provided they are heat-stable. These substrates are common in durable packaging or ID cards.

● Laminated Surfaces: Matte or glossy laminates can handle hot stamping foils if the lamination is heat-resistant. The result is a reflective, high-end finish.

Dragon Foils offers an extensive selection of hot stamping foils in metallic, matte, and holographic finishes. Their foils are engineered for optimal adhesion across diverse substrates, ensuring your designs stay vibrant and long-lasting.

Cold Foils: Expanding Possibilities on Challenging Surfaces

Cold foiling is a versatile alternative to hot stamping. Instead of heat, cold foiling uses UV-curable adhesives and rolls the foil onto the substrate. This method is particularly useful for heat-sensitive materials.

Best Substrates for Cold Foiling:

● Uncoated Papers: Cold foiling works well on uncoated stocks, including kraft papers or recycled papers, which often resist heat.

● Flexible Packaging Films: PET, BOPP, or polypropylene films are ideal for cold foils, commonly used in snack packaging or cosmetic labels.

● Textured or Embossed Papers: Cold foiling can conform to minor surface textures, creating intricate patterns without heat damage.

Dragon Foils cold foils provide exceptional color coverage and adhesion, making them perfect for creative packaging projects where substrate compatibility is a concern.

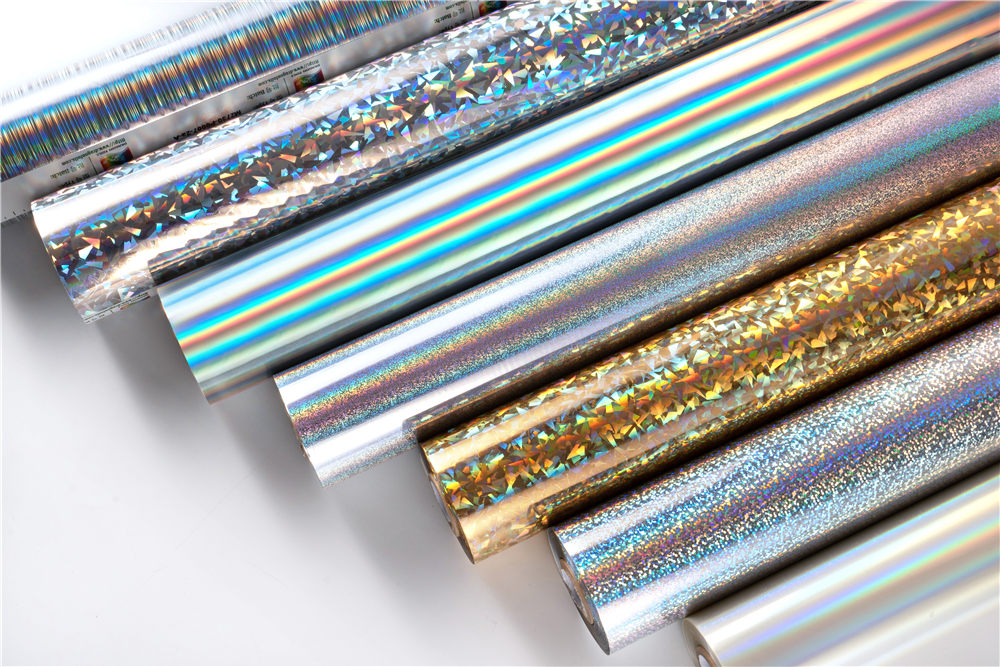

Holographic and Specialty Foils

When the goal is to stand out on the shelf, holographic foils and specialty effects are a game-changer. These foils are designed to create visual depth and dynamic light reflections. However, they require careful substrate consideration.

Suitable Substrates:

● Smooth Coated Surfaces: These offer a clean transfer of holographic patterns and minimize defects.

● Plastics and Laminates: Synthetic substrates can showcase vibrant holographic effects without warping.

● Rigid Packaging Materials: Boxes, cartons, and other rigid surfaces handle holographic foils well, especially in combination with Dragon Foils' premium finishes.

Dragon Foils holographic foils provide a wide range of textures, from subtle shimmering to full rainbow effects, suitable for packaging, labels, and promotional items.

Digital Enhancement Foils: Modern Applications

Digital enhancement foils are designed to integrate seamlessly with digital printing technologies. Unlike traditional foiling methods, these foils can be applied selectively with precision, opening up new creative possibilities.

Ideal Substrates:

● Digital Prints on Coated Paper: Ensure smooth and glossy prints for optimal foil adhesion.

● Flexible Packaging Labels: Used in short-run or customized production, these foils allow intricate designs without the need for expensive dies.

● Marketing Materials: Business cards, brochures, and personalized invitations can benefit from digital enhancement foils, adding a premium touch.

Dragon Foils digital enhancement foils offer compatibility with most digital presses and can be customized to suit branding or packaging projects.

Silk Printing Foils: For Textured and Specialty Applications

Silk printing foils are applied through screen printing techniques, perfect for creating unique textures or layered effects. This method works well for both flat and textured substrates.

Recommended Substrates:

● Textured Papers and Cardstocks: Adds a tactile dimension, ideal for luxury packaging or specialty print products.

● Fabrics and Textiles: Certain silk printing foils can be applied to fabrics for fashion, promotional items, or interior decoration.

● Laminates and Specialty Boards: Works well for embossing effects combined with metallic sheen.

Dragon Foils silk printing foils provide versatility for designers looking to combine texture, metallic finishes, and intricate graphics.

Factors to Consider When Choosing Foils

When selecting a foil for your project, consider these practical factors:

● Heat Sensitivity: Make sure the substrate can tolerate the heat level of hot stamping foils. For sensitive surfaces, cold foils are safer.

● Surface Texture: Smooth surfaces transfer metallic foils well; textured surfaces may need specialized foils or adhesives.

● Flexibility: Flexible substrates like packaging films require foils that can bend without cracking.

● Durability: Consider abrasion resistance for items that will be handled frequently.

● Visual Effect: Match the foil type (metallic, holographic, matte, or digital) with your desired aesthetic and brand identity.

Dragon Foils product range addresses all these factors, making it easier for designers and manufacturers to select the perfect foil based on substrate characteristics.

Practical Tips for Successful Foil Application

Test Before Full Production: Always run small tests to ensure adhesion and color fidelity.

● Check Compatibility: Review manufacturer specifications for both the foil and substrate.

● Consider Coating or Priming: Certain substrates benefit from a primer to improve foil adhesion.

● Combine Techniques: Layering hot stamping and digital enhancement foils can create striking effects, especially on luxury packaging.

By following these tips, you'll minimize waste, ensure a flawless finish, and maximize visual impact.

Conclusion

Choosing the right foil based on substrate material is a critical step in achieving professional, high-quality printing and packaging. From hot stamping foils for traditional elegance to holographic and digital enhancement foils for modern, eye-catching designs, understanding the substrate's properties is key to success.

By aligning your foil selection with the right substrate, you not only enhance aesthetics but also ensure durability and brand value. Dragon Foils offers a comprehensive range of foil solutions—hot stamping foils, cold foils, holographic foils, digital enhancement foils, and silk printing foils—tailored for every substrate type and creative need. Feel free to contact us at export@dragonfoils.com for more.