Hot Stamping Foil Designed for Uneven or Textured Paper

In markets such as wine, cosmetics, confectionery, and luxury goods, textured and uneven papers are often the first choice because they feel authentic, tactile, and premium. Yet these surfaces are notoriously difficult to decorate. Traditional foils struggle to grip the uneven fibers, resulting in incomplete coverage, weak adhesion, or visible bubbles and flakes.

This is where hot stamping foil designed specifically for uneven or textured paper stands out. Instead of forcing print converters to compromise on material choice, this foil is engineered to embrace rough fibers, deep emboss textures, and porous label stock—delivering a clean and metallic finish even at high-speed production.

Hot Stamping Foil for Graphic Printing on Rough Paper Applications

Why Rough and Textured Paper Is So Hard to Stamp?

If you have worked with paper labels or luxury packaging, you already know that the surface can make or break the job. Smooth coated paper behaves predictably, but textured paper introduces three major problems:

Uneven absorption: The raised fibers absorb heat differently, preventing uniform transfer.

Air pockets: Rough papers create micro-gaps between the foil and the paper, which cause bubbles and incomplete coverage.

Low surface “hold”: Metallic layers need something to cling to; when the surface is irregular, adhesion becomes inconsistent.

On prestige applications like wine labels or high-end gift boxes, these imperfections are not tolerated. Consumers expect bold metallic finishes that feel precise and premium, not patchy. A manufacturer might try more pressure or higher temperature, but this often leads to scorching, poor durability, or foil flaking after transport or handling.

A foil engineered for textured surfaces solves these issues not by brute force, but by design: strong bonding layers, flexible transfer film, and heat tolerance that lets the foil mold into fibers instead of sitting awkwardly on top.

What Sets This Hot Stamping Foil Apart?

High-quality rough-paper foils are built with a balance between coverage and flexibility—allowing them to sit confidently on top of textured substrates while preserving the gloss and smoothness associated with premium metallic foil.

Core performance characteristics include:

● High metallic gloss: Even on rough substrates, the foil reflects consistent brightness, avoiding dull patches or washed-out highlights. This matters in brand-critical applications such as wine labels or perfume packaging, where appearance drives perceived value.

● Good coverage and adhesion: Adhesive layers are optimized to “fill in” micro textures. Instead of requiring excessive heat or pressure, the foil naturally seats into the substrate's surface contour, preventing flaking or weak transfer.

● Low stamping temperature: Lower temperature means less stress on printed inks, varnishes, and paper fibers. For label converters and factories running heat-sensitive materials, this dramatically reduces misprints and waste.

● Wide temperature window: Skilled operators know every machine and substrate behaves slightly differently. A foil that performs reliably from 115–150°C on flat-bed systems, 135–170°C on cylinder presses, and 170–220°C on rotary machines gives them breathing room. That range is crucial for stable production without constant recalibration.

● Anti-scratch and rub resistance: Premium labels travel far before reaching the consumer—transport, bottling, handling, shelf movement. Foil that scratches easily becomes expensive waste. Strong abrasion resistance ensures packaging maintains its visual and tactile impact.

● Good transferring performance on medium & large areas: Some foils look fine on narrow text or small icons but fail miserably on large blocks or broad borders. This foil is specifically designed to stamp both medium areas and wide fields without bubbles, voids, or flakes.

● Environmental compliance (ROHS, REACH, VOC): Many packaging buyers—especially international brands—now demand compliance with non-toxic and low-emission materials. Having ROHS, REACH and VOC approvals reduces procurement barriers and ensures global usage.

None of these properties are cosmetic. They are manufacturing protections: fewer mistakes, lower production cost, and higher customer satisfaction.

Real Applications Where the Foil Excels

Because textured substrates are so strongly associated with premium branding, you'll often find this foil used in:

● Wine labels: Textured paper labels for vineyards, especially European wines, have deep fibers that highlight metallic details beautifully when foiled correctly. The reflective silver or matte gold finish emphasizes heritage, tradition, and craftsmanship

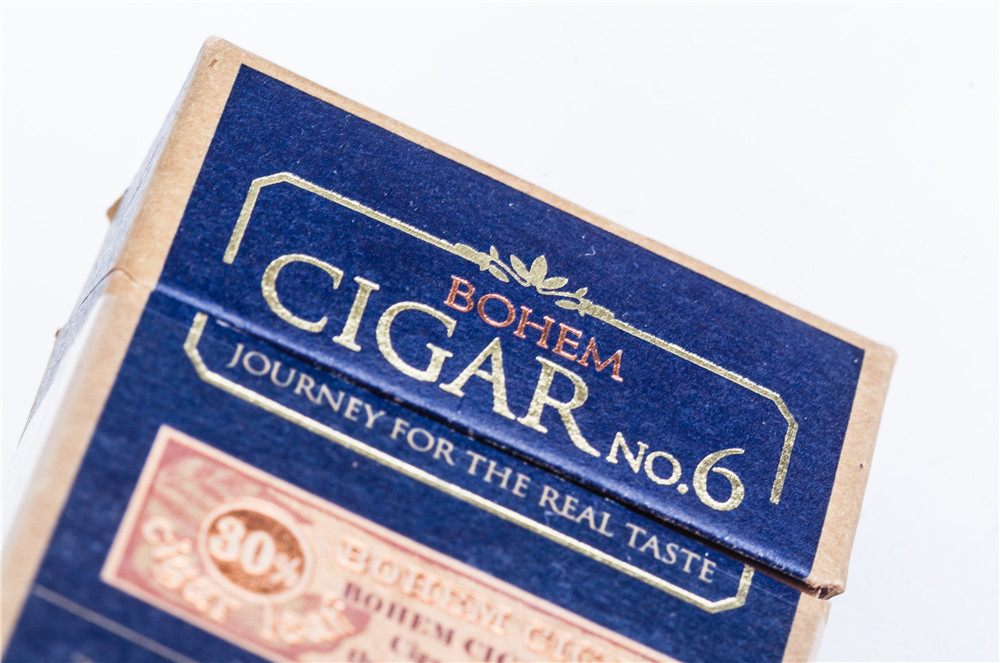

● Cigarette packaging: Cigarette boxes often combine embossing with hot stamping. Their textured boards need stable foil transfer to maintain crisp brand elements and regulatory text.

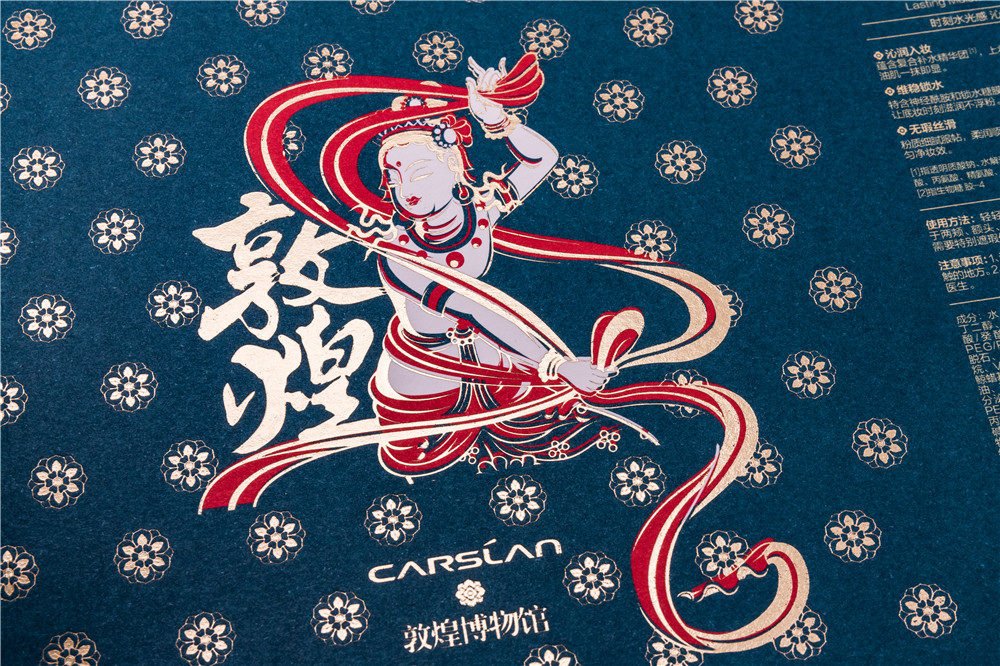

● Cosmetic packaging: Perfume boxes, skincare kits, and cosmetic gift packs use foil to convey softness, elegance, and luxury. Uneven surface treatments—linen paper, embossed paper, or cotton-based cardstock—pair very well with foil.

● Candy and chocolate packaging: These industries frequently leverage gold foil to highlight logos or seasonal messages, where textured carton material keeps the packaging visually warm and less industrial.

● High-end greeting cards: Rough paper stocks feel personal. Foil stamping adds refinement: birthdays, wedding invitations, Christmas cards, or corporate greetings gain visual sophistication.

● Advertising and promotional materials: Brochures, display cards, rigid tags, and artisanal product cards often need foil to stand out on shelves or in trade show environments.

Across these markets, the combination of tactile material + metallic reflection is powerful—it unconsciously signals quality.

Compatible Printing and Stamping Equipment

While foil quality matters, stamping machinery defines production rhythm. The foil we're discussing performs smoothly across multiple press types, which allows converters to scale without investing in new equipment.

● Flat-bed and up-and-down presses: Common in smaller workshops or custom packaging setups. These machines apply precise pressure, ideal for detailed logos or limited-run luxury goods.

● Cylinder machines: Designed for continuous production. The foil's temperature window of 135–170°C on cylinder presses ensures a consistent roll of crisp metallic impressions.

● Rotary machines: The fastest among the three. At 170–220°C, the foil forms clean, durable transfers even at high speed, ensuring output for mass-produced labels or packaging.

This flexibility is essential: brands want consistency, but producers must adapt to machine type, substrate, ink, humidity, and run length. A foil that accommodates all three machine families significantly reduces the risk of unexpected downtime.

Compatible Substrates

Not all foils tolerate surface variance. This one is explicitly tuned for rough surfaces, allowing operators to choose substrates based on design direction—not technical restrictions.

It works with:

● Textured rough paper

● Dry papers and dry labels

● Embossed paper

● Coated paper

● Printed paper

● OPP laminates

That last one—OPP laminates—is particularly notable. Many high-end labels today apply an OPP (or BOPP) film for moisture resistance and durability. Standard foils often struggle on this barrier layer, resulting in lift-off or cold edges. A foil that grips OPP opens the door to wet markets like wine and spirits, where humidity destroys untreated paper.

Color Options and Visual Finish

Visual language matters. A winery founded in 1890 might choose antique matte gold for an old-world feeling. A modern perfume bottle might choose mirror silver to echo minimalist luxury. Flexibility in shade allows packaging designers to tell a more complete story.

Available options typically include:

● Silver / Gold

● Matte Silver / Matte Gold

● Custom colors

These metallic shades reinforce tactile substrates—linen paper, cotton paper, or embossed card—with visual brilliance that ink alone cannot reproduce.

Conclusion: A Better Partner for Premium Packaging

For brands and converters seeking dependable performance on textured and uneven paper, a hot stamping foil engineered specifically for rough substrates is the most reliable solution. It withstands pressure, heat variation, emboss depth, and transport abrasion with elegance, delivering a metallic finish that aligns with luxury, authenticity, and visual impact.

When you need stable supply, professional technical support, or custom color development, Dragon Foils is a smart partner. Our expertise in specialty hot stamping materials—and consistent production quality—helps you deliver packaging that truly elevates your brand.