Difference Between Hot Stamping Foil and Cold Foil

Hot stamping foil and cold foil are both popular methods used in the printing industry to create unique and eye-catching designs.

While they share some similarities, there are also some key differences between the two techniques.

Knowing the difference between hot foil and cold foil, and choosing the right one, will benefit the success of your business.

Hot stamping foil is a process that involves the application of heat and pressure to transfer a metallic or pigmented foil onto a substrate. This technique uses a metal die, which is heated and pressed onto the foil, causing it to release from its carrier and adhere to the substrate. The result is a bright and shiny design that stands out on the printed material.

Hot stamping foil can be used on a variety of materials, including paper, cardboard, plastics, and textiles. It is commonly used in the production of labels, packaging, and promotional materials. Hot stamping foil can create intricate designs and patterns that are difficult to achieve with other printing methods. It also has a high level of durability and resistance to fading and abrasion.

Cold foil, on the other hand, is a process that involves the transfer of a metallic or pigmented foil onto a substrate without the use of heat. This technique uses an adhesive that is printed onto the substrate, and the foil is then applied to the adhesive. The result is a design that has a metallic sheen, similar to hot stamping foil.

Cold foil is commonly used in the printing of labels, packaging, and other promotional materials. It is often used to create a metallic effect that mimics the appearance of hot stamping foil but without the need for heat. One of the advantages of cold foil is that it can be applied in line with other printing processes, which can save time and reduce production costs.

While hot stamping foil and cold foil share some similarities, there are some key differences between the two techniques.

Hot stamping foil requires the use of heat and pressure, while cold foil does not. This can impact the type of materials that can be used, as well as the level of detail that can be achieved.

Hot stamping foil can cover a larger surface area than cold foil, which is limited by the adhesive that is used. This can impact the design options that are available, as well as the level of detail that can be achieved.

Hot stamping foil is generally more durable and resistant to fading and abrasion than cold foil. This makes it a popular choice for labels and packaging that require a high level of durability.

Deciding which technique to use will depend on a number of factors, including the materials being used, the design requirements, and the level of durability needed.

Hot stamping foil is best suited for materials that can withstand heat and pressure, and for designs that require a high level of detail and durability.

Cold foil is best suited for materials that cannot withstand heat, and for designs that require a metallic effect without the use of heat.

In terms of cost, hot stamping foil is generally more expensive than cold foil, due to the need for specialized equipment and the use of heat. Cold foil, on the other hand, can be applied in line with other printing processes, which can save time and reduce production costs.

In a word, hot stamping foil and cold foil are two distinct techniques used in the printing industry to create metallic or pigmented designs.

Both techniques have their advantages and disadvantages, and the decision to use one over the other will depend on various factors, such as the materials being used, the design requirements, and the level of durability needed.

Ultimately, choosing the right technique for your printing needs will depend on careful consideration of these factors to achieve the desired results.

While they share some similarities, there are also some key differences between the two techniques.

Knowing the difference between hot foil and cold foil, and choosing the right one, will benefit the success of your business.

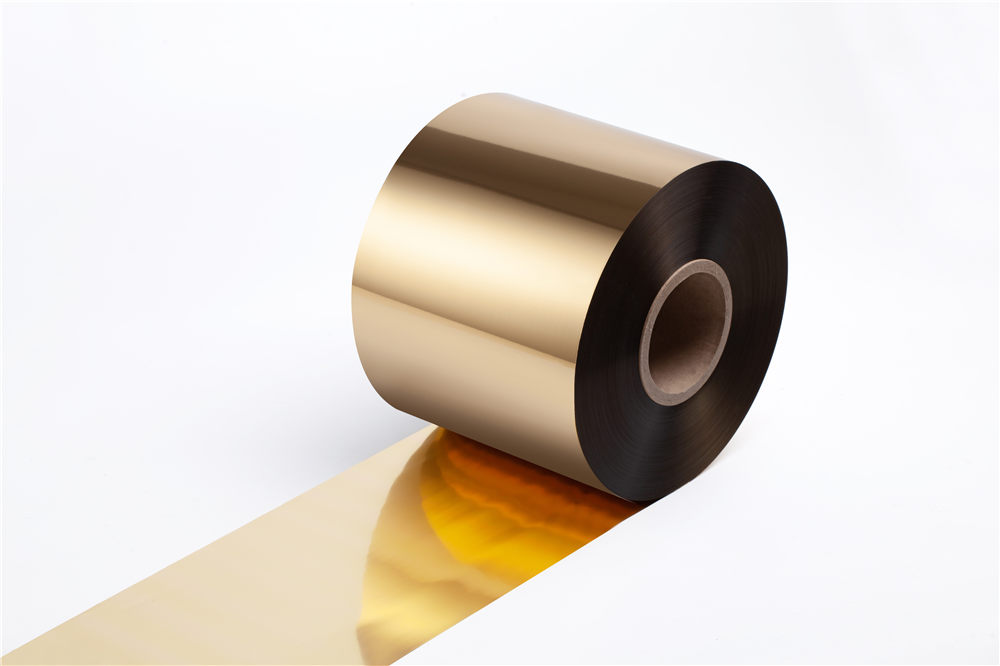

What is Hot Stamping Foil?

Hot stamping foil is a process that involves the application of heat and pressure to transfer a metallic or pigmented foil onto a substrate. This technique uses a metal die, which is heated and pressed onto the foil, causing it to release from its carrier and adhere to the substrate. The result is a bright and shiny design that stands out on the printed material.

Hot stamping foil can be used on a variety of materials, including paper, cardboard, plastics, and textiles. It is commonly used in the production of labels, packaging, and promotional materials. Hot stamping foil can create intricate designs and patterns that are difficult to achieve with other printing methods. It also has a high level of durability and resistance to fading and abrasion.

What is Cold Foil?

Cold foil, on the other hand, is a process that involves the transfer of a metallic or pigmented foil onto a substrate without the use of heat. This technique uses an adhesive that is printed onto the substrate, and the foil is then applied to the adhesive. The result is a design that has a metallic sheen, similar to hot stamping foil.

Cold foil is commonly used in the printing of labels, packaging, and other promotional materials. It is often used to create a metallic effect that mimics the appearance of hot stamping foil but without the need for heat. One of the advantages of cold foil is that it can be applied in line with other printing processes, which can save time and reduce production costs.

Differences between Hot Stamping Foil and Cold Foil

While hot stamping foil and cold foil share some similarities, there are some key differences between the two techniques.

The most significant difference is the application process.

Hot stamping foil requires the use of heat and pressure, while cold foil does not. This can impact the type of materials that can be used, as well as the level of detail that can be achieved.

Another difference between the two techniques is the level of coverage.

Hot stamping foil can cover a larger surface area than cold foil, which is limited by the adhesive that is used. This can impact the design options that are available, as well as the level of detail that can be achieved.

Hot stamping foil and cold foil also differ in terms of their durability.

Hot stamping foil is generally more durable and resistant to fading and abrasion than cold foil. This makes it a popular choice for labels and packaging that require a high level of durability.

Which Technique is Best for Your Printing Needs?

Deciding which technique to use will depend on a number of factors, including the materials being used, the design requirements, and the level of durability needed.

Hot stamping foil is best suited for materials that can withstand heat and pressure, and for designs that require a high level of detail and durability.

Cold foil is best suited for materials that cannot withstand heat, and for designs that require a metallic effect without the use of heat.

In terms of cost, hot stamping foil is generally more expensive than cold foil, due to the need for specialized equipment and the use of heat. Cold foil, on the other hand, can be applied in line with other printing processes, which can save time and reduce production costs.

Conclusion

In a word, hot stamping foil and cold foil are two distinct techniques used in the printing industry to create metallic or pigmented designs.

Both techniques have their advantages and disadvantages, and the decision to use one over the other will depend on various factors, such as the materials being used, the design requirements, and the level of durability needed.

Ultimately, choosing the right technique for your printing needs will depend on careful consideration of these factors to achieve the desired results.